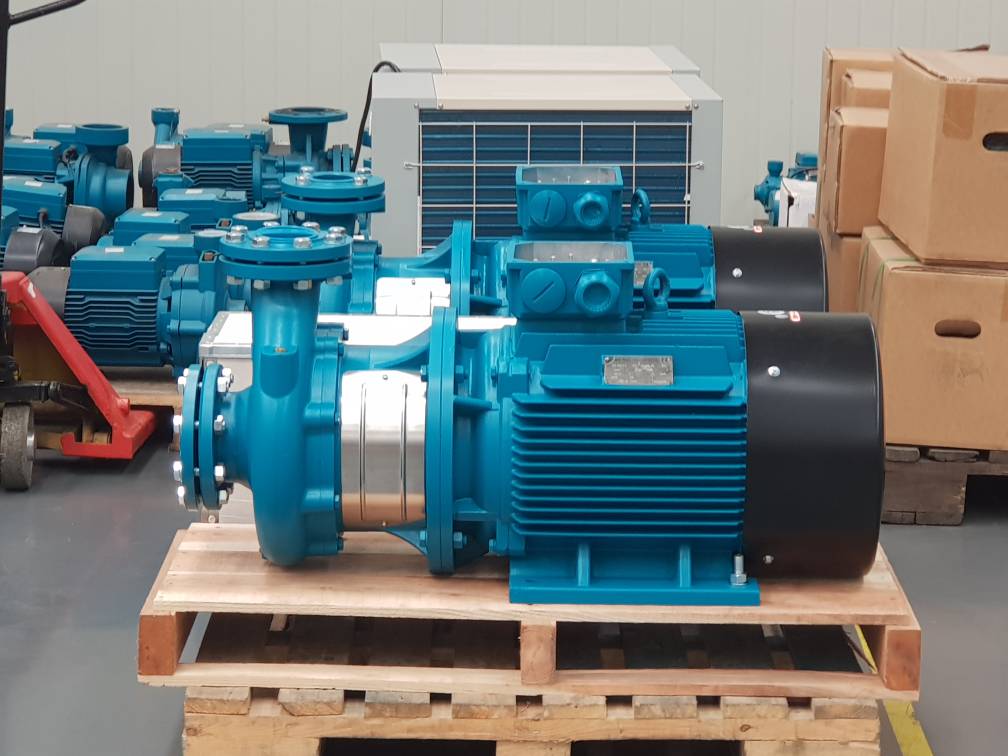

Description

- KDM series are non-self priming, horizontal, ring portions radially divided, multistage centrifugal pumps.

- Impeller is between bearings; it is single-entry, closed impeller and dynamically balanced.

- There is a balancing drum at discharge side to balance axial load.

- The pump and motor is fixed on the same chassis and are connected via a flexible coupling to each other.

- Suction and discharge press nozzles can be selected in different 90° positions.

- Specially designed fans provide extra cooling to the bearings.

- Bearings lubricated by the liquid.

- Axial loads balanced with balancing drum and thus seal pressure is decreased. High efficiency has been achieved due to the low leakage flow.

- There is a level indicator for oil level in the bearing housing.

- There is thermometer to see the oil temperature while running.

- Emergency measures for both oil and temperture levels.

- Angular contact ball bearings are used. These bearings have a longer life even under extreme working hours.

- Soft packing or mechanical seal is used for sealing.

Application Areas

- Power plants

- Pumping clean and sligghtly contaminated fluids

- Boiler feed and condensate transfer

- Central heating systems

- Water supply system

- High-rise buildings and industry booster sets

- Water purification

- Industrial washing system

- Sanitary and cleaning facilities

- Industrial applications and utilities

- Water delivery services

- Shipbuilding, mining, filter units

Reviews

There are no reviews yet.